Steel Buckler

Classwork - 2020

Materials: Sheet steel (18 gauge), rectangular stock steel, wooden dowel, leather, FEV mixture (denatured alcohol, shellac, alcohol-based leather dye)

This steel buckler was a class project to explore the shaping of sheet steel. I began by pulling a design online and scaling it up to an appropriate buckler size. I cut the circle out with a plasma cutter and cleaned up the sharp edges with a grinder. From there, I hammered out the base shape and center, following up with a round of planishing to smooth out the dented steel. The center was plasma cut, and another hammered piece was MIG welded in. I added an inner rim with stock steel and another round of welding.

Once this was cleaned with a grinder, I created a handle from bent and shaped steel strips covered in shaped wood and leather. This was attached with another weld and a false rivet was welded on. The design was scaled to fit the buckler and engraved in with a dremel. Once everything was clean, I used a shellac and leather dye FEV coating to shift the color of the piece to a tarnished bronze.

Finished Buckler Front

Finished Buckler Back

Finished Buckler Back

Engraved Finished Front - No FEV

Cleaned Front

Handle Attached on Back w/ Rough Clean

Finished Welded Front - Pre-Clean

Rim and Center Welded on - Pre-Clean

Front After Planishing

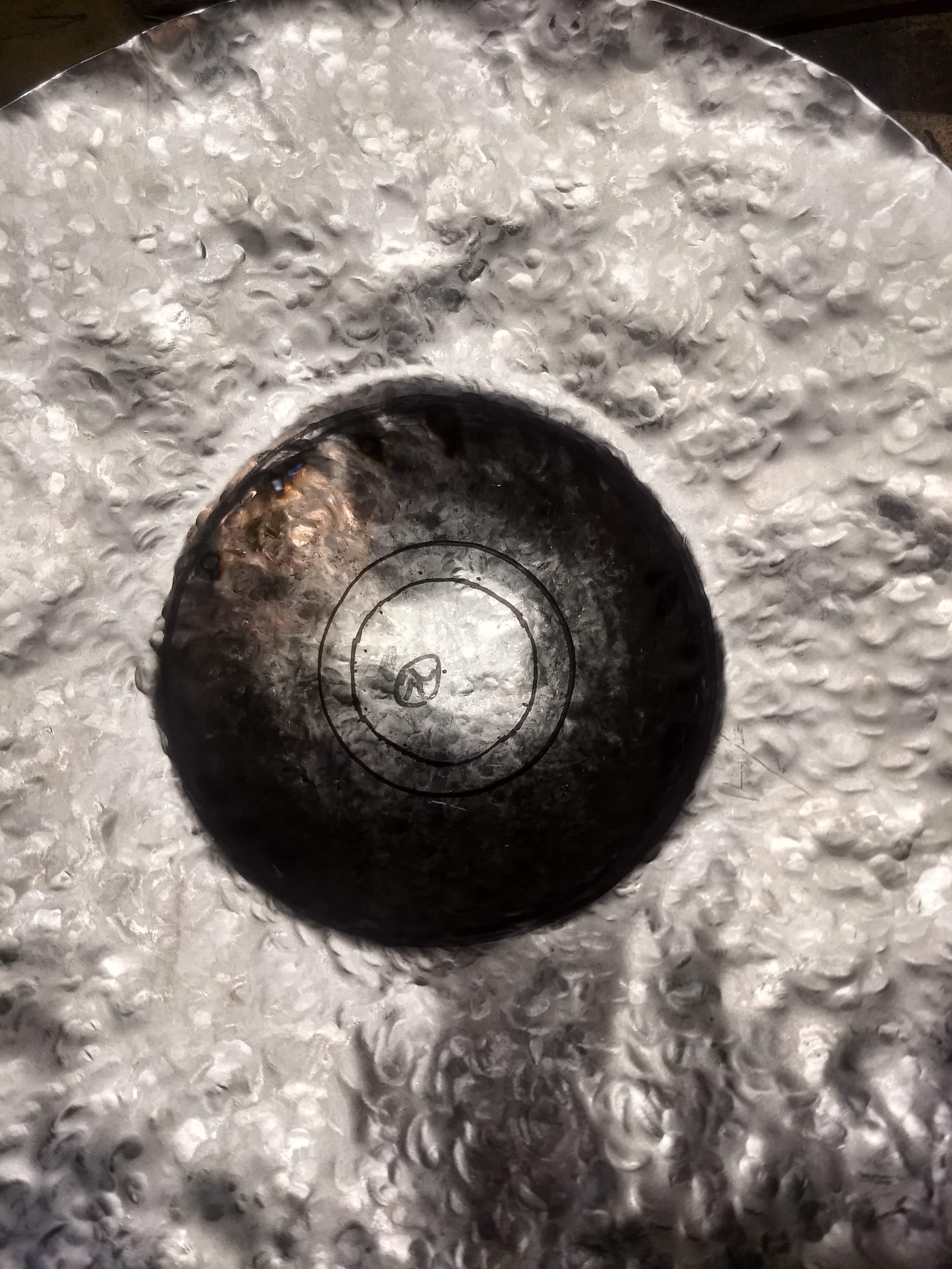

Center Bowl

Rough Bowled Steel Base